"With winter rapidly approaching, it is important to protect workers from the coming cold temperatures and potential extreme weather. Prolonged exposure to these conditions can result in serious health problems, including trench foot, hypothermia and frostbite. Extreme cases can even result in death. Although the Occupational Safety and Health Administration (OSHA) has no specific standards pertaining to work in cold environments, employers are obligated to provide a workplace free of recognized hazards, including those caused by winter weather.

In general, outdoor work requires preparation. However, in the winter months, it calls for additional planning. Employees should be trained on winter hazard recognition, identifying and monitoring themselves for signs of cold stress, and they should know actions to take if they exhibit these symptoms. It is important to note that people who are in poor physical condition or have predisposed medical conditions, such as hypertension, hypothyroidism and diabetes, are at a higher risk of sustaining an injury or illness as a result of cold stress. Emergency help should be sought immediately if someone is experiencing uncontrolled shivering, slurred speech, clumsy movements, fatigue, or confused behavior.

Encourage workers to protect themselves from cold, wet and windy conditions by dressing accordingly. OSHA suggests wearing multiple layers to provide better insulation and to help adjust to changing temperatures. OSHA's winter weather guide recommends, "An inner layer of wool, silk or synthetic (polypropylene) to keep moisture away from the body, a middle layer of wool or synthetic to provide insulation even when wet; and an outer wind and rain protection layer that allows some ventilation to prevent overheating."

OSHA also indicates that a knit hat should be worn along with insulated, waterproof boots and gloves. Of course, when working around energized lines or circuit parts, all winter clothing must also meet arc-resistant ratings.

When working in the cold, it is important to stay dry. Any moisture or dampness caused by sweat, snow or rain can increase the rate of body heat loss. Therefore, having an extra set of dry clothes is always a good idea when working in winter conditions. Tight clothing should be avoided because it can reduce blood flow and result in more rapid heat loss.

Outdoor work in the winter should be scheduled at the warmest time of the day. Employers and employees should pay attention to weather conditions during winter storms and have a reliable means of communications with each other. This can be helpful if a work stoppage or evacuation becomes necessary. Being aware of and monitoring severe weather indicators, such as outdoor sirens, radio and television, can be helpful, as well. In addition, workers can better monitor each other for cold stress symptoms if they work in pairs.

Employers should provide a warm, dry place for workers to take breaks from freezing temperatures. Exhaustion and fatigue in cold weather can result in a higher rate of body heat loss. Provide warm beverages and sports drinks for employees, and inform them that avoiding caffeine and alcohol can help them maintain a warmer body temperature. Employees should also consider eating warm, high-calorie foods, such as pasta, when preparing to work in cold environments.

Other measures an employer can take to protect workers include providing the right tools for the job, offering de-icing solutions for tools or equipment, shielding work areas from wind or providing radiant heaters.

Fuel-burning heaters should be used outdoors only because they emit carbon monoxide. Electricians should never use a fuel-burning heater indoors or in any enclosed area.

Linemen and wiremen attempting to restore power in winter conditions must use extra caution, as well.

OSHA's winter weather guide states, "Repairing and/or replacing damaged power lines in severe winter weather conditions are especially hazardous. A major hazard is snow, because the moisture can reduce the insulation value of protective equipment, and could cause electrocution. In these conditions de-energized work is safer, but if energized work must be done, qualified workers and supervisors must first do a hazard analysis that includes evaluating the weather conditions and identifying how to safely do the job."

Remember that de-energized lines should be treated as if they are energized, and you should never touch metal surfaces with your bare hands.

If you would like more information regarding cold and winter weather safety, OSHA's website (www.osha.gov) provides numerous resources, or you can check out the National Institute of Safety and Health cold stress guide (www.cdc.gov/niosh/topics/coldstress)."

Source: http://www.ecmag.com/section/youre-gonna-need-bigger-coat

Tuesday, November 24, 2015

Tuesday, November 17, 2015

Tuesday, November 10, 2015

"Why Remote Video Verification Makes All the Difference" - Xtralis

"Most people understand the basic premise of the intruder alarm system: detectors are strategically positioned in a building, with door contacts and a control panel that are usually connected to internal and external sirens on site, and then are connected via a standard telephone line to a Central Monitoring Station (CMS). Most customers are under the illusion that this protects their premises, but in reality it doesn't make the doors any stronger or the windows any tougher, they still break when struck. Nothing actually stops the intruder from getting into the building other than deterring them with the promise of a response.

An intruder alarm system is really just designed to detect an intruder AFTER they have broken into the premises and at best will limit the time an intruder spends on the premises since they know the authorities have been notified. In a single sentence, an intruder alarm system is 'designed to limit loss.'

False alarms can and do happen, and oftentimes the primary causes of false alarms are actually quite simple. It boils down to poorly designed and installed security systems or human operating error. Even something as harmless as the positioning of an advertising module or display near a ventilation outlet may result in a false alarm when it moves in the air currents. A 'break-in' might actually be nothing more than a display that tips over and triggers the alarm. And while CCTV is great for recording what happens as evidence in the event of a break-in (or for things like parking lot surveillance), if the intruder is wearing a mask or a cap and their face cannot be identified all you really have is a recording of the loss.

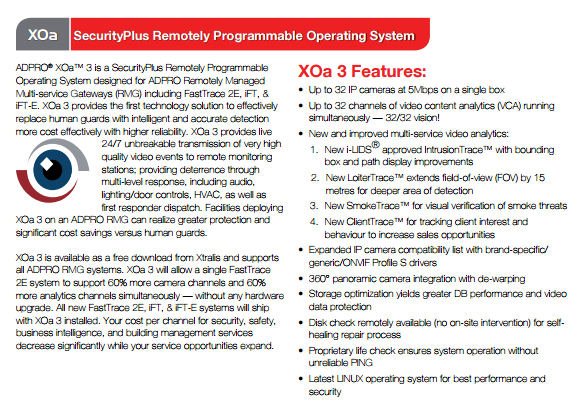

However, remote video verification from a centralized monitoring location can help protect a building AND better account for real and false alarms. A remote off-site video verification system includes a detection device that covers the same field of view as the CCTV camera. The cameras and detectors are connected to an ADPRO transmitter. The ADPRO system is then connected to the customer's public address system or an amplifier with speakers sited eternally around the premises. On site the customer has complete control of the CCTV system as an onsite surveillance system. The difference is that when the customer vacates the premises and arms the intruder alarm they also arm the ADPRO system.

If an intruder approaches the building, when they enter the field of view of the camera, the ADPRO system 'grabs' three frames of video from that camera at 1-second intervals and dials through to the Central Monitoring System. In the Control Room the attending operator receives these three frames of video on a single Quad screen along with a fourth video image that replays all three frames of video in a video loop, to ensure that the operator can clearly determine what generated the alarm. This way the operator knows if the alarm is actually something that needs to be addressed, or if it's just a false alarm. The operator can then switch to live video from that camera of select any camera to view. The operator can observe someone on site, and simply use a microphone to challenge the intruder with a simple warning such as 'You in the grey jumper, you have activated a remote video alarm system please leave the site immediately!' This way the intruder knows they are being actively watched by someone!

The operator could operate any PTZ camera from the CMS and obtain a good image of the intruder prior to warning the intruder off. This may in turn be forwarded to the police for appropriate action. A customer can also control access to the site by motorizing the access gates, installing an intercom at the gates and connecting the remote outputs to the ADPRO system.

Having remote video verification allows businesses and organizations to save money. Many municipalities will issue fines for false alarms to cover the costs of dispatching police or other personnel. Video verification alerts the operator as if something that triggered the alarm is in fact an intruder, or if it is something due to human error. In some areas, having alarm verification is a requirement for a security system. Some city police departments will not respond to a building alarm unless the alarm has been verified as a 'true alarm' first. Without a verification of the alarm, the police may not respond which could leave the building vulnerable if an intruder is in-fact trying to get in.

The success of video alarm verification has been clearly demonstrated by the installation of ADPRO products on tens of thousands of large scale commercial, industrial and government sites around the world. These installations are well-engineered, integrated solutions, comprising a variety of outdoor and/or indoor sensor technologies and a combination of CCTV and video transmission systems."

Source: http://blog.xtralis.com/?p=120

An intruder alarm system is really just designed to detect an intruder AFTER they have broken into the premises and at best will limit the time an intruder spends on the premises since they know the authorities have been notified. In a single sentence, an intruder alarm system is 'designed to limit loss.'

False alarms can and do happen, and oftentimes the primary causes of false alarms are actually quite simple. It boils down to poorly designed and installed security systems or human operating error. Even something as harmless as the positioning of an advertising module or display near a ventilation outlet may result in a false alarm when it moves in the air currents. A 'break-in' might actually be nothing more than a display that tips over and triggers the alarm. And while CCTV is great for recording what happens as evidence in the event of a break-in (or for things like parking lot surveillance), if the intruder is wearing a mask or a cap and their face cannot be identified all you really have is a recording of the loss.

However, remote video verification from a centralized monitoring location can help protect a building AND better account for real and false alarms. A remote off-site video verification system includes a detection device that covers the same field of view as the CCTV camera. The cameras and detectors are connected to an ADPRO transmitter. The ADPRO system is then connected to the customer's public address system or an amplifier with speakers sited eternally around the premises. On site the customer has complete control of the CCTV system as an onsite surveillance system. The difference is that when the customer vacates the premises and arms the intruder alarm they also arm the ADPRO system.

If an intruder approaches the building, when they enter the field of view of the camera, the ADPRO system 'grabs' three frames of video from that camera at 1-second intervals and dials through to the Central Monitoring System. In the Control Room the attending operator receives these three frames of video on a single Quad screen along with a fourth video image that replays all three frames of video in a video loop, to ensure that the operator can clearly determine what generated the alarm. This way the operator knows if the alarm is actually something that needs to be addressed, or if it's just a false alarm. The operator can then switch to live video from that camera of select any camera to view. The operator can observe someone on site, and simply use a microphone to challenge the intruder with a simple warning such as 'You in the grey jumper, you have activated a remote video alarm system please leave the site immediately!' This way the intruder knows they are being actively watched by someone!

The operator could operate any PTZ camera from the CMS and obtain a good image of the intruder prior to warning the intruder off. This may in turn be forwarded to the police for appropriate action. A customer can also control access to the site by motorizing the access gates, installing an intercom at the gates and connecting the remote outputs to the ADPRO system.

Having remote video verification allows businesses and organizations to save money. Many municipalities will issue fines for false alarms to cover the costs of dispatching police or other personnel. Video verification alerts the operator as if something that triggered the alarm is in fact an intruder, or if it is something due to human error. In some areas, having alarm verification is a requirement for a security system. Some city police departments will not respond to a building alarm unless the alarm has been verified as a 'true alarm' first. Without a verification of the alarm, the police may not respond which could leave the building vulnerable if an intruder is in-fact trying to get in.

The success of video alarm verification has been clearly demonstrated by the installation of ADPRO products on tens of thousands of large scale commercial, industrial and government sites around the world. These installations are well-engineered, integrated solutions, comprising a variety of outdoor and/or indoor sensor technologies and a combination of CCTV and video transmission systems."

Source: http://blog.xtralis.com/?p=120

Tuesday, November 3, 2015

Electrical engineer's work may signal better wireless connections. Exciting.

Dr. Aria Nosratinia, a University of Texas - Dallas electrical engineering professor, is currently investigating how to improve wireless connections.

The wireless space we have now may become too crowded in the future, which may interfere with efficiency and function. Nosratinia aims to "develop methods that break the wireless messages into microstreams, or smaller pieces, enabling them to be transmitted through -- rather than against -- other signals in the environment. We use this method together with liquid-metal antennas, which allows us to change radiation patterns effectively and reduce interference."

This study is an expansion of a previous project in which Nosratinia discovered "a new dimension in the communication over multi-user wireless channels," providing "a new set of tools to address the challenges of transmission in a wireless medium, and therefore improves the quality of wireless communication."

So far, the research has received a $608,000 award to support a collaboration with researchers from the University of Hawaii, a $421,000 grant to expand on the previously mentioned discovery regarding the behavior of wireless channels, and an approximately $1.13 million collaboration to investigate hardware Trojans with another University of Texas - Dallas electrical engineering professor, Dr. Yiorgos Makris.

The wireless space we have now may become too crowded in the future, which may interfere with efficiency and function. Nosratinia aims to "develop methods that break the wireless messages into microstreams, or smaller pieces, enabling them to be transmitted through -- rather than against -- other signals in the environment. We use this method together with liquid-metal antennas, which allows us to change radiation patterns effectively and reduce interference."

This study is an expansion of a previous project in which Nosratinia discovered "a new dimension in the communication over multi-user wireless channels," providing "a new set of tools to address the challenges of transmission in a wireless medium, and therefore improves the quality of wireless communication."

So far, the research has received a $608,000 award to support a collaboration with researchers from the University of Hawaii, a $421,000 grant to expand on the previously mentioned discovery regarding the behavior of wireless channels, and an approximately $1.13 million collaboration to investigate hardware Trojans with another University of Texas - Dallas electrical engineering professor, Dr. Yiorgos Makris.

Subscribe to:

Posts (Atom)